Strength member for fiber optic cables, usually located at the center of fiber optic cables, is one important component of fiber optic cables by supporting optic fiber bundle and enhancing cables tensile strength. Traditionally strength member is metal wire. Non-metallic FRP strength member are widely used in various fiber optic cables due to their advantages like low weight, high strength, anti-corrosion and long service life.

FRP Rod / FRP strength member is made by thermal pultrusion technique

which combines complex resin as body material with glass fiber as reinforcement at certain ratio. Without drawbacks of traditional metallic strength member, FRP rod features excellent anti-corrosion, electromagnetic interference free, high tensile strength, low weight, saving energy and environmentally friendly, which are now widely used in various optical fiber cables.

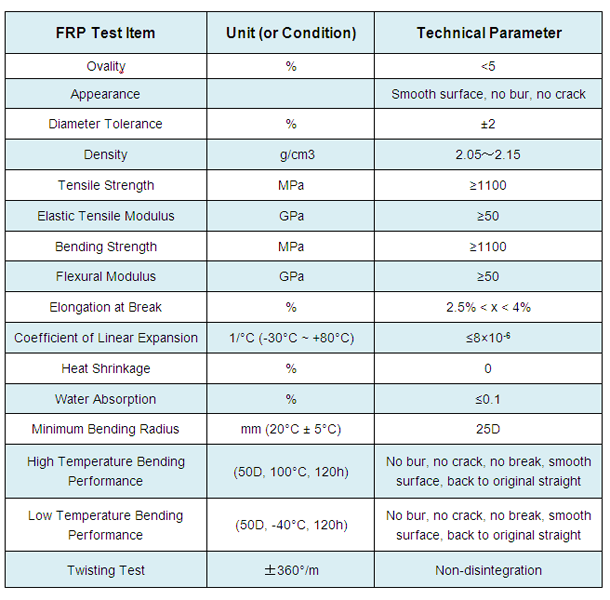

(1) High tensile strength, high modulus, low heat conductivity, low stretch, low expansion, wide range of temperature settings.

(2) Insensitive to electric shock, suitable for the area with frequent lightning and raining.

(3) Free from chemical corrosion. Compared with metal wire, FRP rod eliminates harmful gas, which can negatively affect cables transmission quality, born chemically by metal and filling gel.

(4) Compared with metal wire, FRP rod is of high strength, low weight, excellent insulation and immune to electromagnetic interference.

(5) Optical fiber cables with FRP rod are available to be installed tight close to power wire and power units, perfectly insulated, free from induction current interference. The transmission efficiency can be improved accordingly.

(6) Smooth surface, stable sizes, easy processing and installation contribute to wide range of FRP strength member application.

Diameter range (F 0.40 ~ 5.00mm with very close diameter tolerance)

Normal Diameter F (mm)

| 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 0.90 | 1.00 | 1.10 | 1.20 | 1.30 | 1.40 |

| 1.50 | 1.60 | 1.70 | 1.80 | 1.90 | 2.00 | 2.10 | 2.20 | 2.30 | 2.40 | 2.50 |

| 2.60 | 2.70 | 2.80 | 3.00 | 3.30 | 3.40 | 3.50 | 3.80 | 4.00 | 4.60 | 5.00 |

Normal Length

Diameter (F0.40-F2.3 mm) Standard Delivery Length 50.4 km/drum or customerized;

Diameter (F2.40-F3.5 mm) Standard Delivery Length 25.2 km/drum or customerized;

Diameter (F3.60-F5.0 mm) Standard Delivery Length 12.5 km/drum or customerized;

NOTE: Diameter or length of non-standard sizes can be customized.

Flat FRP Specification

| 0.60x1.30mm | 0.70x3.00mm | 1.00x3.00 mm | 1.20x3.80mm | 1.27x3.00mm | 1.40x3.00mm | 1.60x3.00mm |

Normal Length:

Thickness ( = 1.00mm) Standard Delivery Length =25km splice free Length measurement and marking by METER

Thickness ( = 1.20mm) Standard Delivery Length =15km splice free Length measurement and marking by METER

Note: Thickness or length of non-standard size can be customized.

FRP Rod - Packing

FRP Rod - Storage

(1) Cable reels can only stand upright. Lying flat or piling up are prohibited.

(2) Cable reels long distance rolling is prohibited.

(3) Keep away from heavy impact, squeezing or any mechanical damage.

(4) Keep away from moisture, long time sun exposure or rain.

(5) Storage and transportation temperature: - 40癈 ~ + 60癈

Contact: MISS WANG

Phone: +86 158 6160 2379

Tel: +86 510-8601 1827

Email: info@hongbofrp.com

Web: http://www.hongbofrp.com

Add: No. 28, Songwentou Road, Yunting Street, Jiangyin City, Jiangsu Province,China